What is the key factors for the construction binding wires in production procedure?

Galvanized iron wire has many different wire diameters, and different wire diameters have different uses. Among them, the construction steel bar binding is one of the main uses.

Galvanized iron wire has many different wire diameters, and different wire diameters have different uses. Among them, the construction steel bar binding is one of the main uses.

Here according to 15 years production experience of construction binding wires, HEBEI SHAOMAN will give an explanation about the key factors that have great impaction on quality.

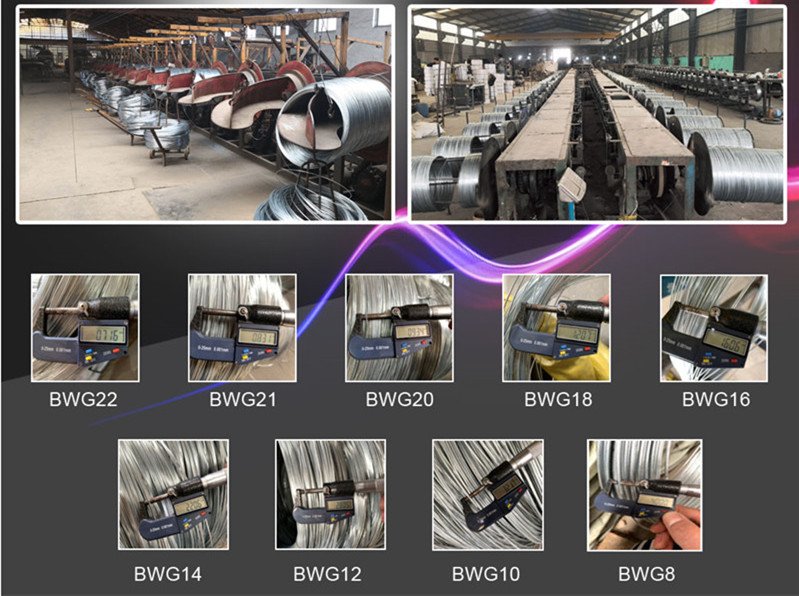

The diameter of construction binding wires usually includes: BWG23 (0.61mm), BWG22 (0.71mm), BWG21 (0.83mm), BWG20, BWG18(1.2mm), BWG16(1.65mm). In the production process of construction wires, the key points mainly include the following 4 points:

1. Raw material:

Hebei Shaoman purchases the highest quality Q195 low-carbon steel wire rod (Zhongyang wire rod) as raw material, which is the basis for the quality of iron wire.

2. Wire drawing:

Draw the wire rod from 6.5mm to 2.1mm, and then from 2.1mm to the corresponding wire diameter. At present, the fully automatic touch screen digital control wire drawing equipment adopted by Hebei Shaoman has a high degree of automation, small difference in wire diameter, and uniform wire drawing force. All these ensure the stability of the product very well.

3. Annealing:

After the wire drawing is completed, the iron wire should be put into a closed high-pressure furnace and burned for 7.5 hours, then kept at a constant temperature in the high-pressure furnace for 16 hours, taken out of the furnace, and placed in a drying area to cool naturally for 8 hours to 100 Below ℃, then open the cover to take the wires. The current state-of-the-art high-pressure, closed furnace annealing can make the softness of the iron wire consistent, and there will be no scale on the surface of the iron wire, and the brightness will be higher.

4. Packing:

After annealing and galvanizing, we will have professional workers to pack the products. Make sure that the packaging material and weight of each bundle meet customer requirements.

Hebei Shaoman is very careful in every procedure of production. If you have requirements on construction binding wires, welcome to contact us. Hebei Shaoman will be your best partner.